Introduction

Twist Bioscience's High-Throughput Antibody Production is a gene-to-protein workflow that relieves this bottleneck by producing tens to thousands of diverse antibodies for screening biophysical and pharmacokinetic properties. Twist’s silicon-based DNA synthesis platform can precisely write thousands of genes per run, enabling the rapid and high-throughput production of antibodies for discovery and screening.

Bonus! We offer downstream characterization and screening services for all high-throughput antibody production orders. This offering includes affinity ranking, epitope binning, and more!

Immediately expand your antibody production pipeline. Simply upload the antibody sequences you need and let Twist do the rest. Learn more on how to order your antibodies from the ordering tab!

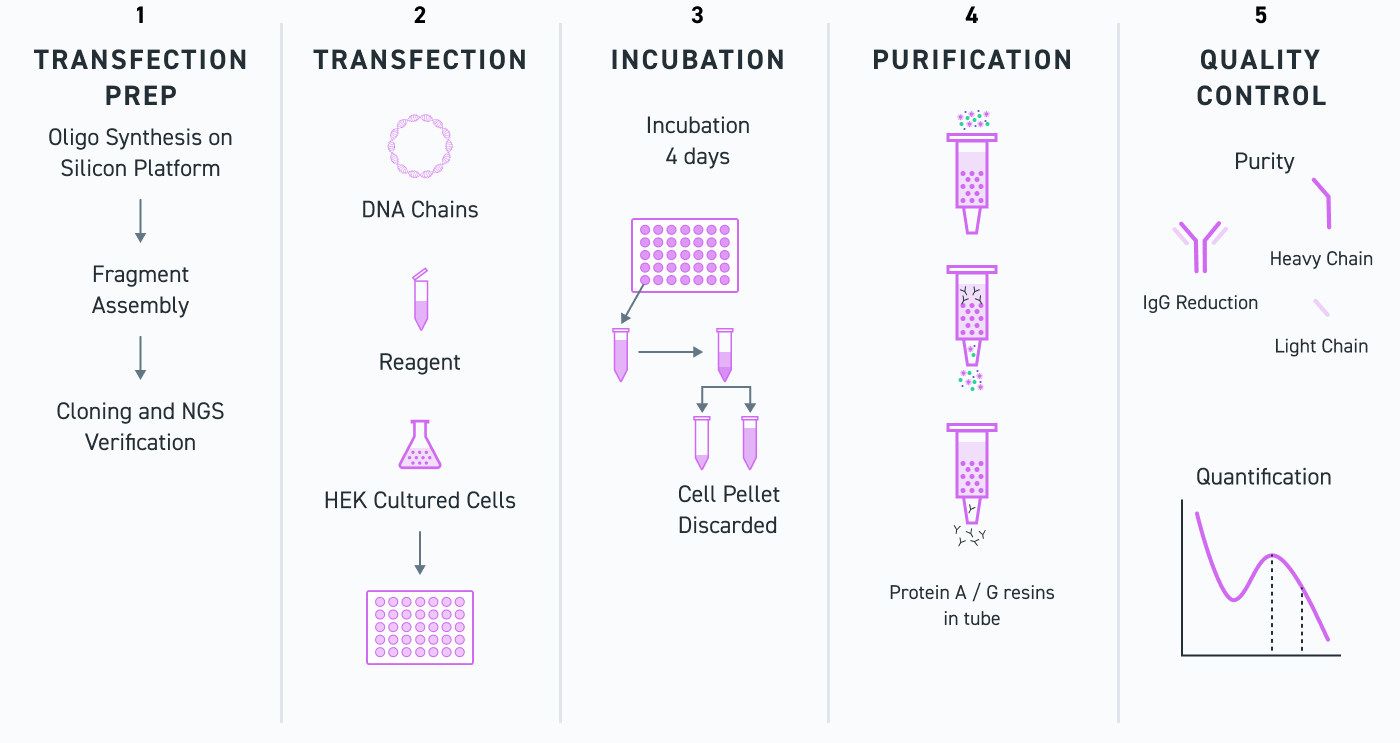

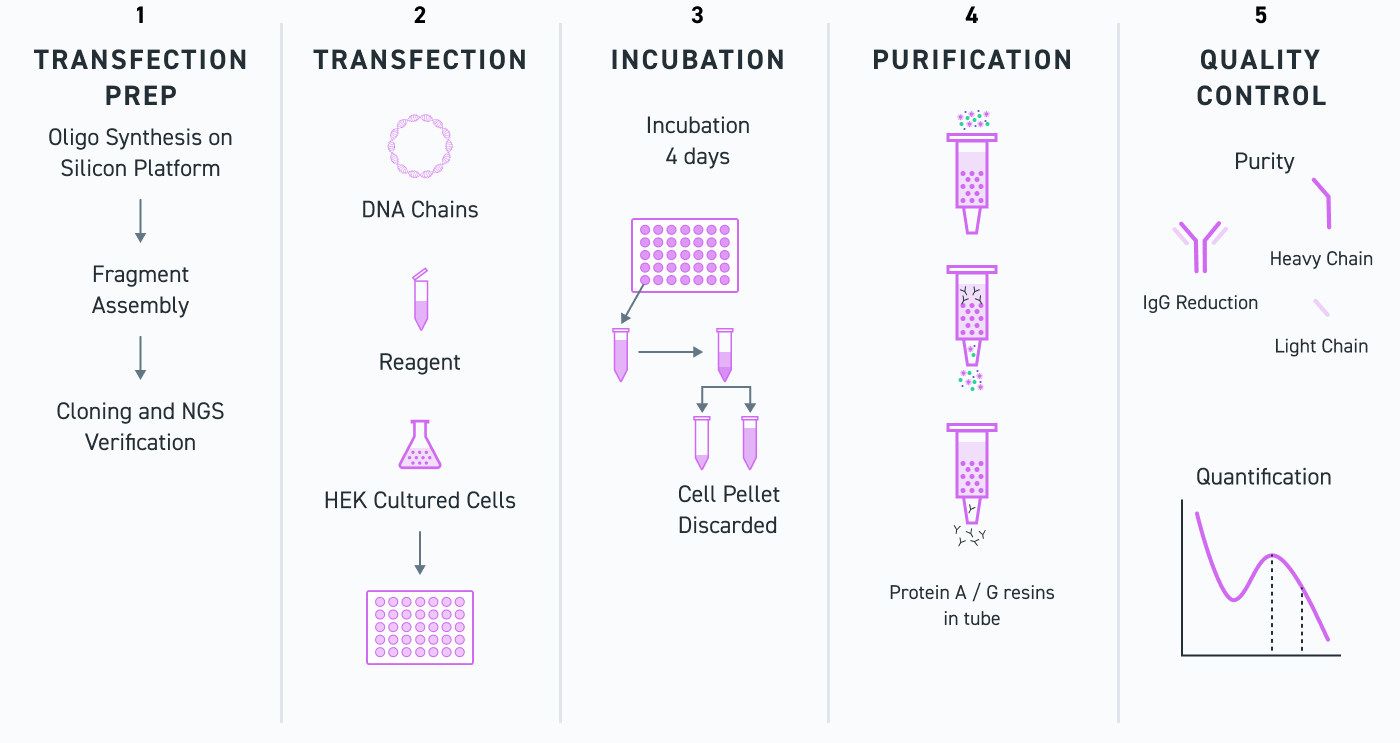

How does it work?

Briefly, Twist synthesizes and clones heavy, light, or single-chain variable sequences into Fc-containing vectors. Paired heavy and light chain or single-chain genes are then transfected into HEK293 cells for a period of 4 days. Supernatants containing the secreted antibodies are harvested and purified using Protein A/G. Purified antibodies are inspected for concentration, size and purity information using A280 and digital CE-SDS, respectively.

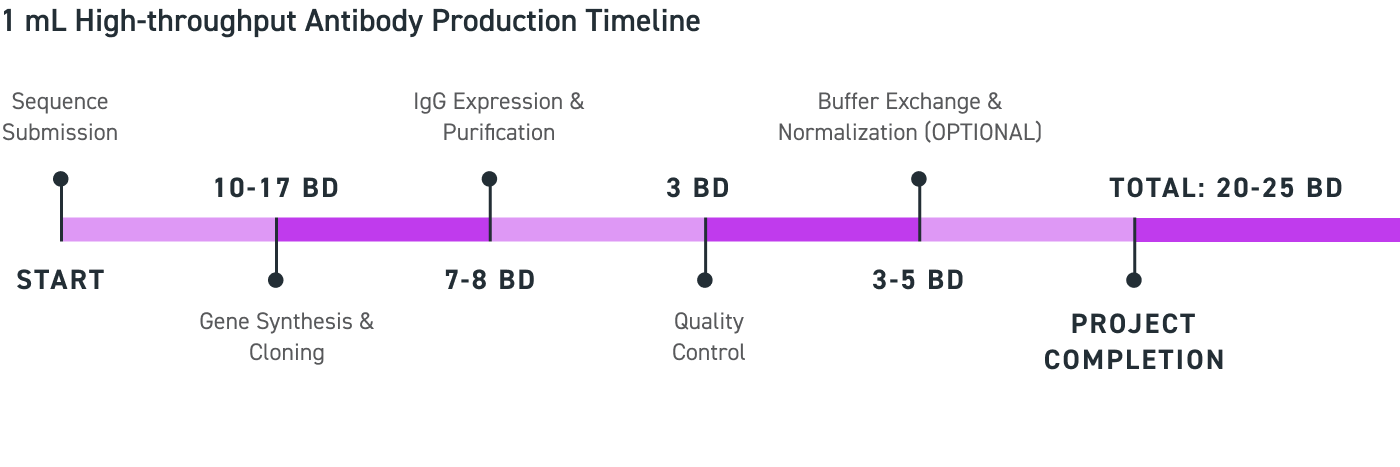

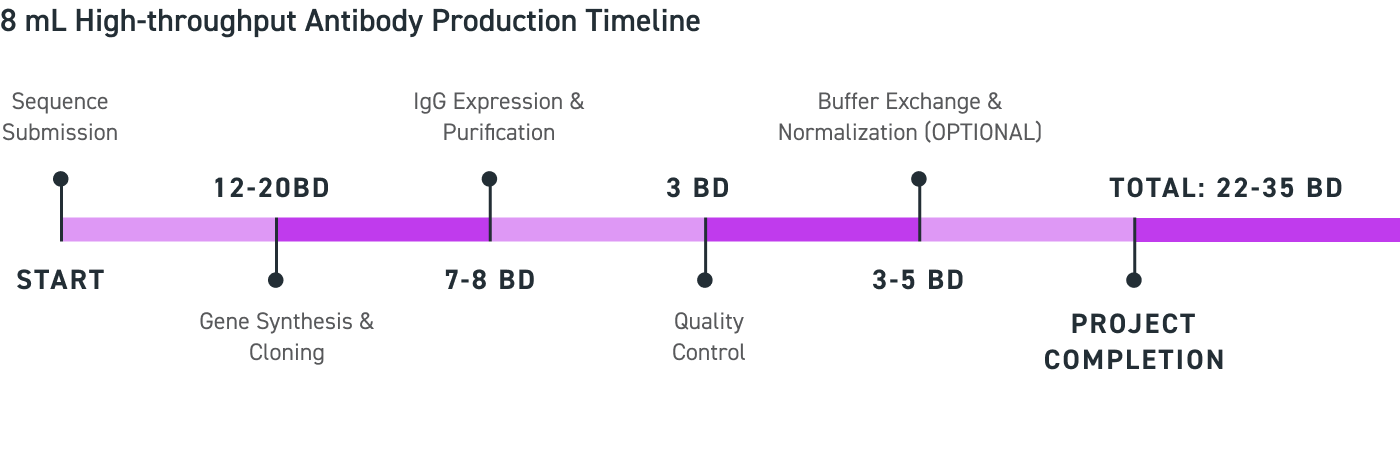

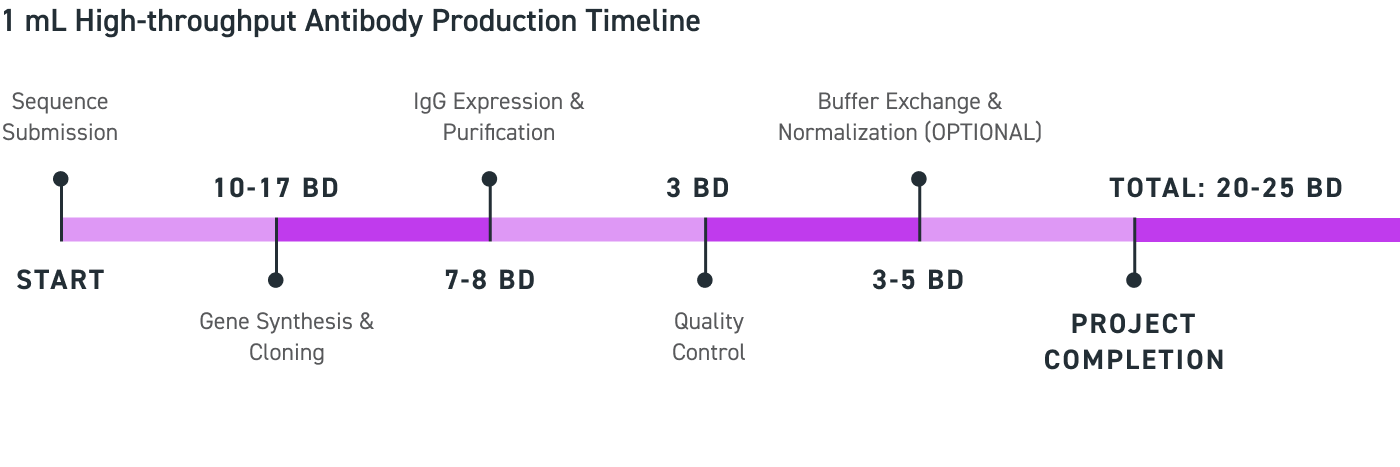

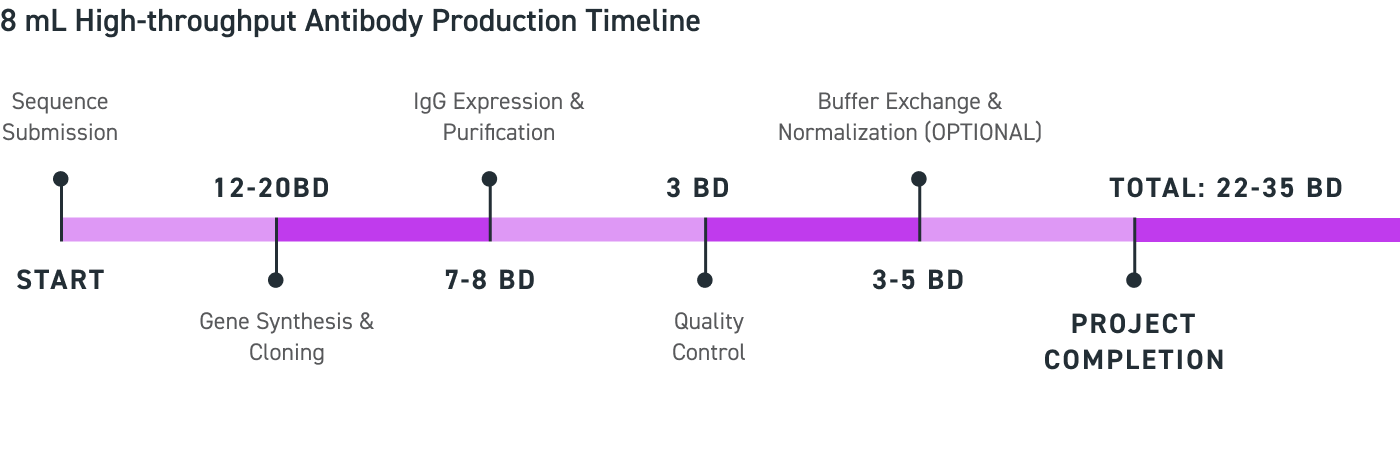

How long does this process take?

From sequence submission to delivery, expect your antibodies from 20-25 business days for 1 mL orders and 22-35 business days for 8 mL orders.

Need to expand your capacity for producing antibodies for screening?

Twist High throughput Antibody Production enables immediate expansion of your antibody production pipeline. Simply upload the antibody sequences you need and let Twist do the rest.

Learn how Twist helped relieve the biologics bottleneck caused by the low-throughput, resource-intensive process of designing, synthesizing, and characterizing antibody variants in the discovery pipeline with our gene to protein workflow which results in antibodies ready for screening.

Introduction

Twist Bioscience's High-Throughput Antibody Production is a gene-to-protein workflow that relieves this bottleneck by producing tens to thousands of diverse antibodies for screening biophysical and pharmacokinetic properties. Twist’s silicon-based DNA synthesis platform can precisely write thousands of genes per run, enabling the rapid and high-throughput production of antibodies for discovery and screening.

Bonus! We offer downstream characterization and screening services for all high-throughput antibody production orders. This offering includes affinity ranking, epitope binning, and more!

Immediately expand your antibody production pipeline. Simply upload the antibody sequences you need and let Twist do the rest. Learn more on how to order your antibodies from the ordering tab!

How does it work?

Briefly, Twist synthesizes and clones heavy, light, or single-chain variable sequences into Fc-containing vectors. Paired heavy and light chain or single-chain genes are then transfected into HEK293 cells for a period of 4 days. Supernatants containing the secreted antibodies are harvested and purified using Protein A/G. Purified antibodies are inspected for concentration, size and purity information using A280 and digital CE-SDS, respectively.

Need to expand your capacity for producing antibodies for screening?

Twist High throughput Antibody Production enables immediate expansion of your antibody production pipeline. Simply upload the antibody sequences you need and let Twist do the rest.

How long does this process take?

From sequence submission to delivery, expect your antibodies from 20-25 business days for 1 mL orders and 22-35 business days for 8 mL orders.

Learn how Twist helped relieve the biologics bottleneck caused by the low-throughput, resource-intensive process of designing, synthesizing, and characterizing antibody variants in the discovery pipeline with our gene to protein workflow which results in antibodies ready for screening.

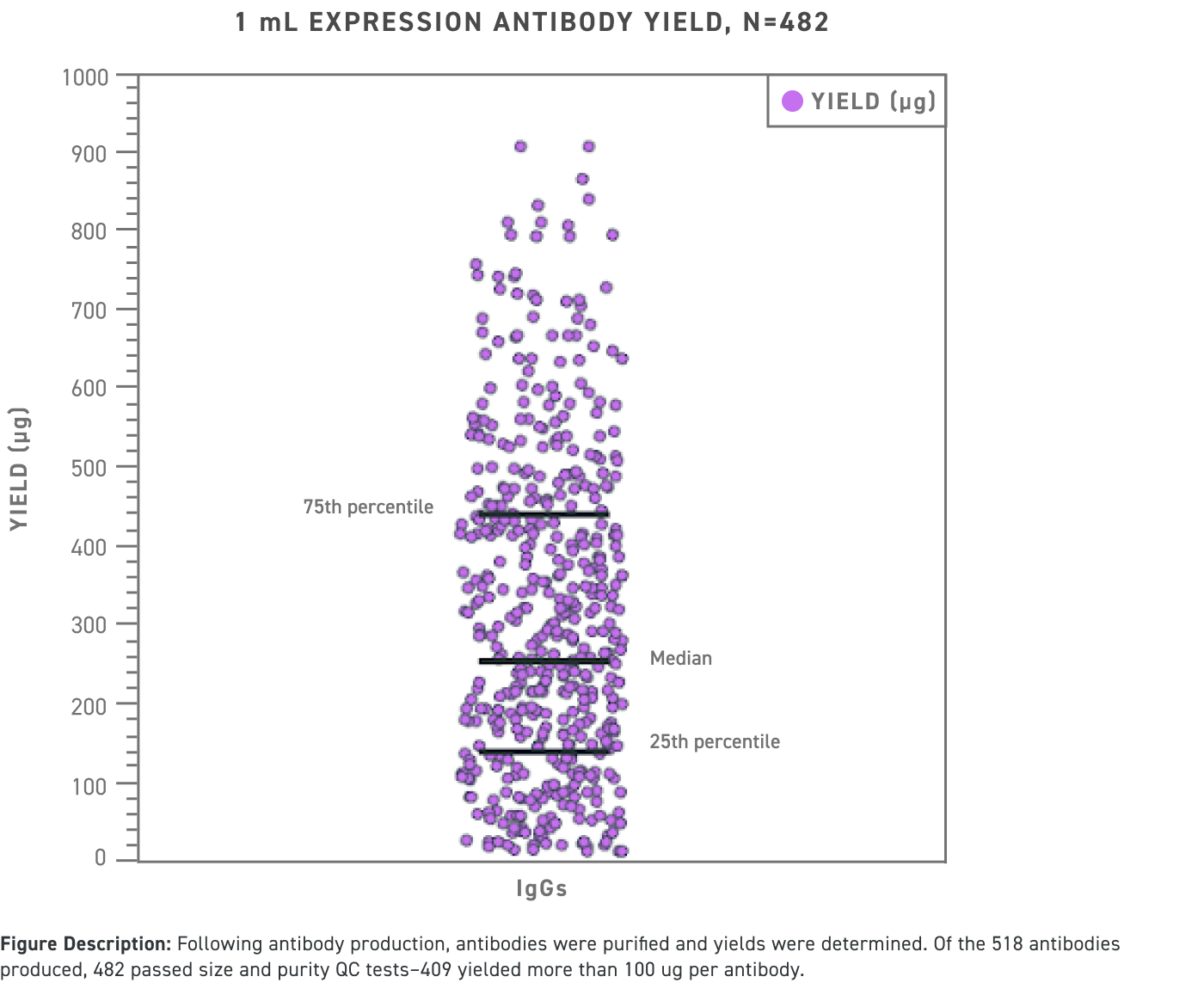

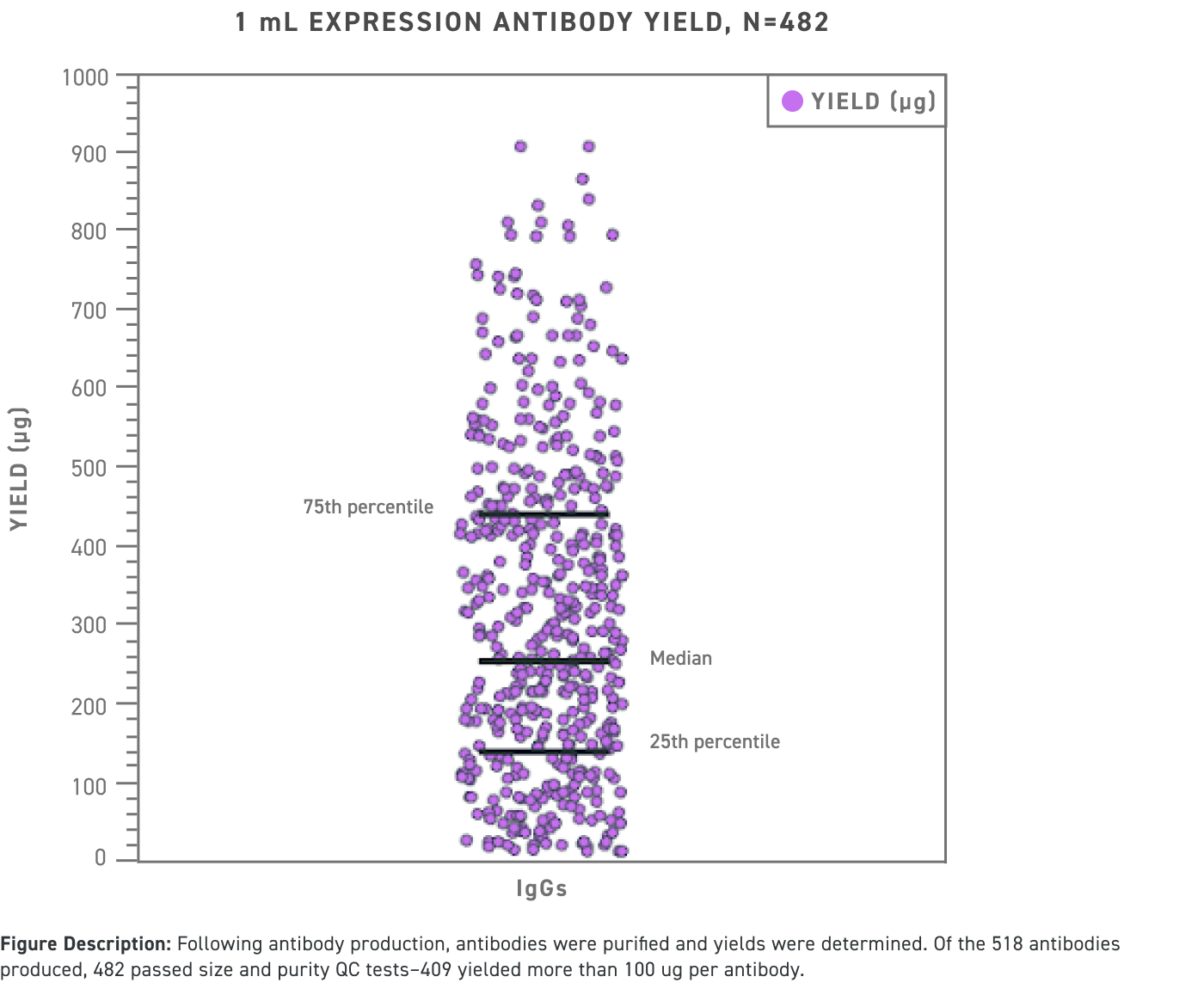

Figure description: Following antibody production, antibodies were purified and yields were determined. Of the 518 antibodies produced, 482 passed size and purity QC tests–409 yielded more than 100 ug per antibody.

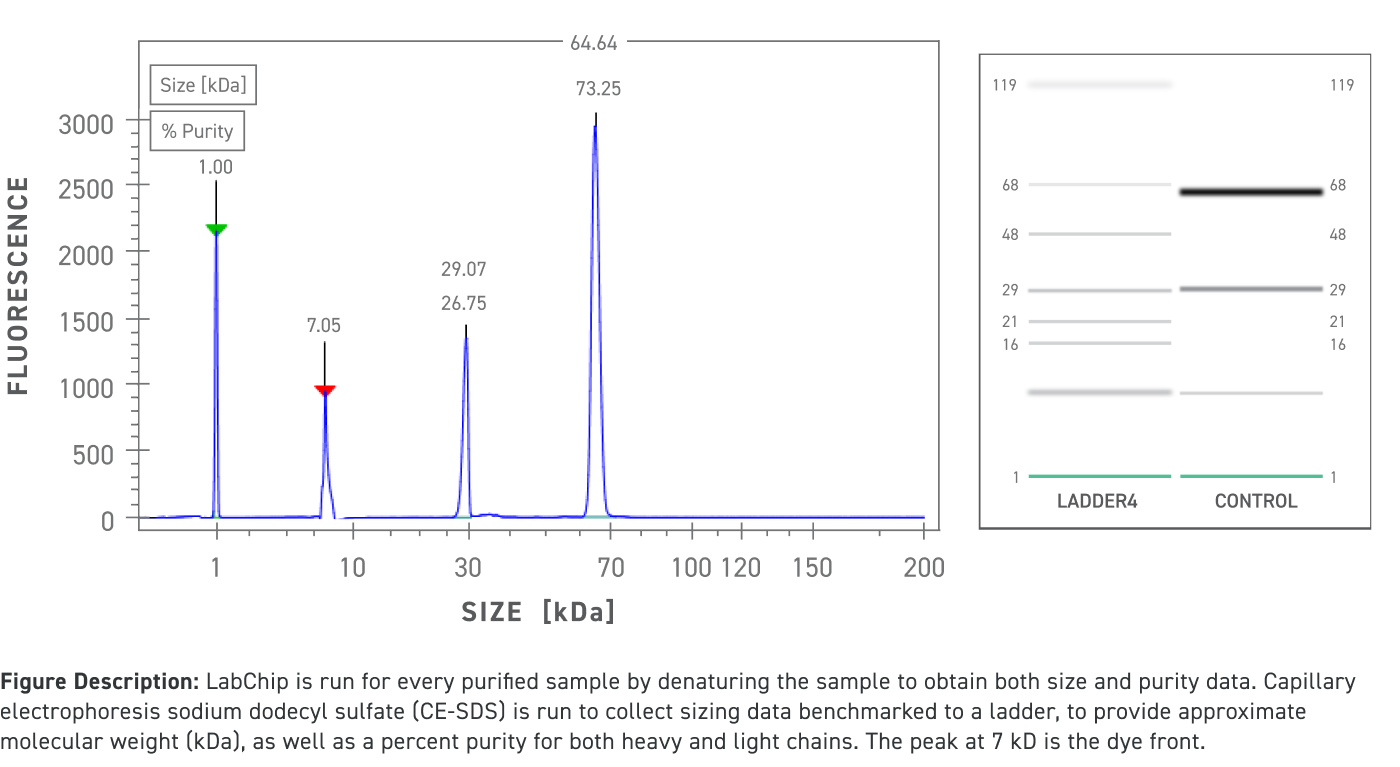

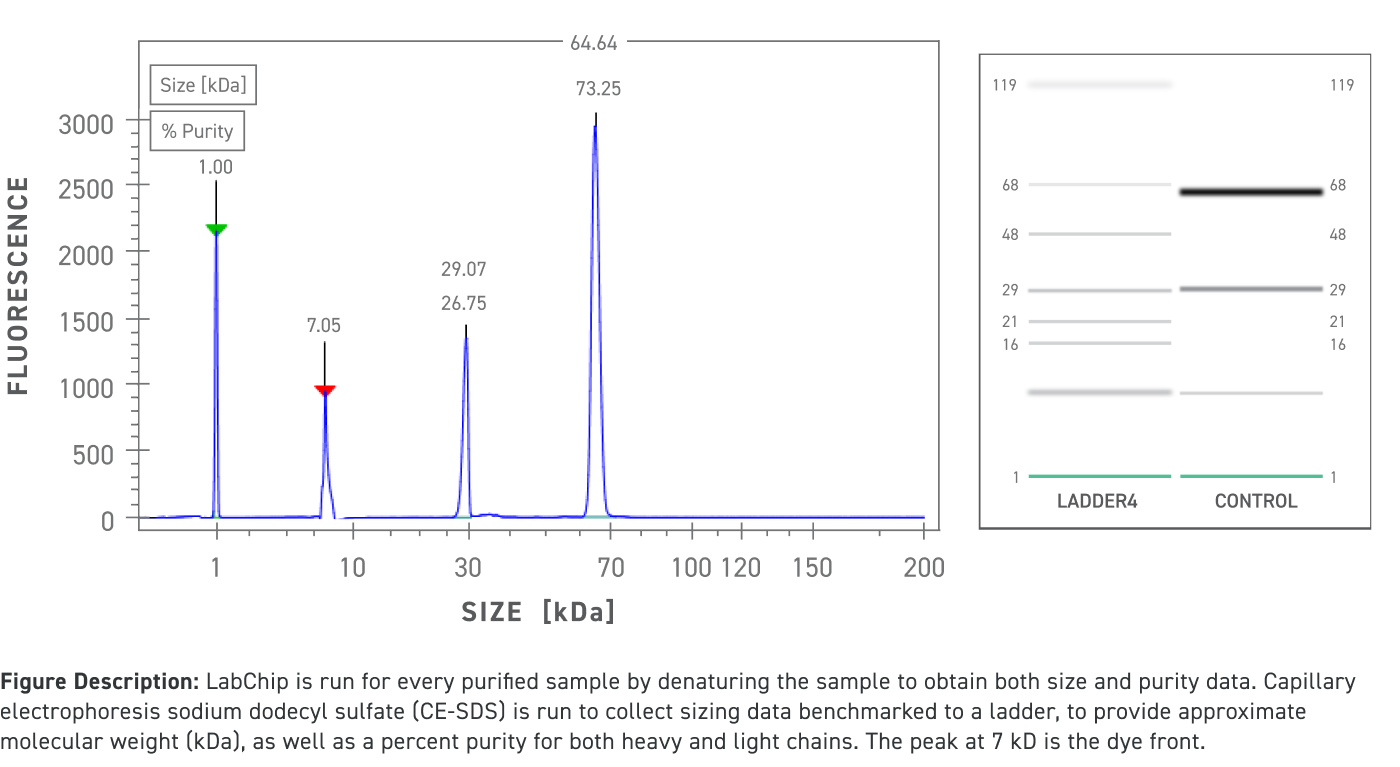

LabChip is run for every purified sample by denaturing the sample to obtain both size and purity data. Capillary electrophoresis sodium dodecyl sulfate (CE-SDS) is run to collect sizing data benchmarked to a ladder, to provide approximate molecular weight (kDa), as well as a percent purity for both heavy and light chains. The peak at 7 kD is the dye front.

Want to see more data on things like affinity and titer levels? Download our flyer!

Figure description: Following antibody production, antibodies were purified and yields were determined. Of the 518 antibodies produced, 482 passed size and purity QC tests–409 yielded more than 100 ug per antibody.

LabChip is run for every purified sample by denaturing the sample to obtain both size and purity data. Capillary electrophoresis sodium dodecyl sulfate (CE-SDS) is run to collect sizing data benchmarked to a ladder, to provide approximate molecular weight (kDa), as well as a percent purity for both heavy and light chains. The peak at 7 kD is the dye front.

Want to see more data on things like affinity and titer levels? Download our flyer!

Product Sheet

This document will provide you detailed information on Twist Bioscience’s High-Throughput Antibody Production offering, including product specifications, customizations, and more.

Guide/Guideline

This Quick start guide will walk you through the process of preparing your sequences and placing an order within Twist’s ordering platform.

Guide/Guideline

Recommended handling and storage instructions for Twist Hight Throughput IgG

Flyer

Wist's platform is designed to provide robust expression of antibody candidates with yields generated for potential antibody hits against a specific antigen. Learn about the expression data Twist will provide you in this flyer.

Product Sheet

This document will provide you detailed information on Twist Bioscience’s High-Throughput Antibody Production offering, including product specifications, customizations, and more.

Guide/Guideline

This Quick start guide will walk you through the process of preparing your sequences and placing an order within Twist’s ordering platform.

Guide/Guideline

Recommended handling and storage instructions for Twist Hight Throughput IgG

Flyer

Wist's platform is designed to provide robust expression of antibody candidates with yields generated for potential antibody hits against a specific antigen. Learn about the expression data Twist will provide you in this flyer.

To place an order through our eCommerce portal, simply prepare your trimmed variable region sequences according to our Quick start guide and paste them into our upload template along with the corresponding antibody names. Once the file is uploaded, the portal will ask for the IgG subtype, light chain type, expression vectors (Twist provided or custom), and to specify the Kozak and leader sequences to use. Once the sequences are screened and reviewed, simply select the scale (1 mL vs. 8 mL), grade (pure vs. supernatant), elution buffer, buffer exchange (optional), and delivery format to complete your order!

To place an order through our eCommerce portal, simply prepare your trimmed variable region sequences according to our Quick start guide and paste them into our upload template along with the corresponding antibody names. Once the file is uploaded, the portal will ask for the IgG subtype, light chain type, expression vectors (Twist provided or custom), and to specify the Kozak and leader sequences to use. Once the sequences are screened and reviewed, simply select the scale (1 mL vs. 8 mL), grade (pure vs. supernatant), elution buffer, buffer exchange (optional), and delivery format to complete your order!

General

Delivery Format

Resources and Guidance for Sequence Design

-

abYsis provides an integrated, comprehensive, and annotated sequence assessment for one or multiple antibodies. AbYsis provides a thorough regional breakdown of antibody sequences to quickly identify where your variable region starts and ends. A tabular breakdown of the leader, FWK, and CDR sequences as well as the tail, or constant region sequence is also provided.

-

It can be helpful to apply the annotations provided by abYsis to your sequence using bioinformatic programs to help visualize and isolate your variable region. Below is an example of a sequence imported to the Geneious Prime software platform with abYsis annotations applied.

-

One additional option that may provide comprehensive breakdown of leader, variable, and constant regions is ANARCI. The resulting analysis provides the exact variable region sequence highlighted in red, which can then be uploaded to the Antibodies application on our eCommerce website. ANARCI also provides detail on the light chain domain type and the sequence species.

-

Please keep in mind that variable region sequences should never start with a methionine (M). If you are uploading sequences that start with the amino acid M, or nucleotides ATG, and are planning to use pTwist vectors, please contact our support for assistance.

-

Reformatting variable domains from one species to another can be complicated given differences between disulfide bonding and other features. By default, the Twist eCommerce platform will not correct any of these issues. We typically rely on you to account and inspect for these type of reformatting complications. If you need assistance, please contact our support team.

General

Delivery Format

Resources and Guidance for Sequence Design

-

abYsis provides an integrated, comprehensive, and annotated sequence assessment for one or multiple antibodies. AbYsis provides a thorough regional breakdown of antibody sequences to quickly identify where your variable region starts and ends. A tabular breakdown of the leader, FWK, and CDR sequences as well as the tail, or constant region sequence is also provided.

-

It can be helpful to apply the annotations provided by abYsis to your sequence using bioinformatic programs to help visualize and isolate your variable region. Below is an example of a sequence imported to the Geneious Prime software platform with abYsis annotations applied.

-

One additional option that may provide comprehensive breakdown of leader, variable, and constant regions is ANARCI. The resulting analysis provides the exact variable region sequence highlighted in red, which can then be uploaded to the Antibodies application on our eCommerce website. ANARCI also provides detail on the light chain domain type and the sequence species.

-

Please keep in mind that variable region sequences should never start with a methionine (M). If you are uploading sequences that start with the amino acid M, or nucleotides ATG, and are planning to use pTwist vectors, please contact our support for assistance.

-

Reformatting variable domains from one species to another can be complicated given differences between disulfide bonding and other features. By default, the Twist eCommerce platform will not correct any of these issues. We typically rely on you to account and inspect for these type of reformatting complications. If you need assistance, please contact our support team.